Troubleshooting methods for ten common inverter faults

August 20, 2024

1. The keyboard has no display after power-on

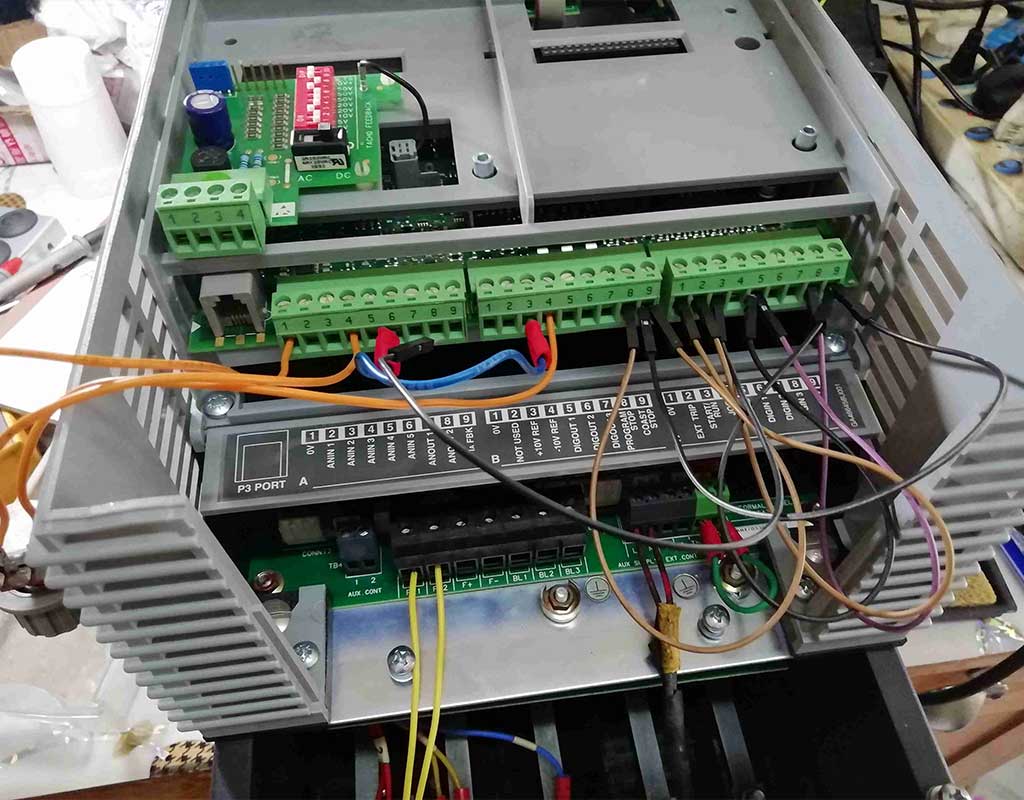

1.1 Check whether the input power supply is normal. If it is normal, measure the voltage at the P and N terminals of the DC bus to see if it is normal. If there is no voltage, turn off the power to check whether the charging resistor is damaged or short-circuited.

1.2 After checking, the voltage of P and N terminals is normal. You can replace the keyboard and keyboard cable. If there is still no display, you need to turn off the power and check whether the 26P cable connecting the main control board and the power board is loose or damaged.

1.3 If the switch power supply works normally after power-on, the relay has a closure sound, the fan runs normally, but there is still no display, it can be determined that the crystal oscillator or resonant capacitor of the keyboard is broken. At this time, the keyboard can be replaced or repaired.

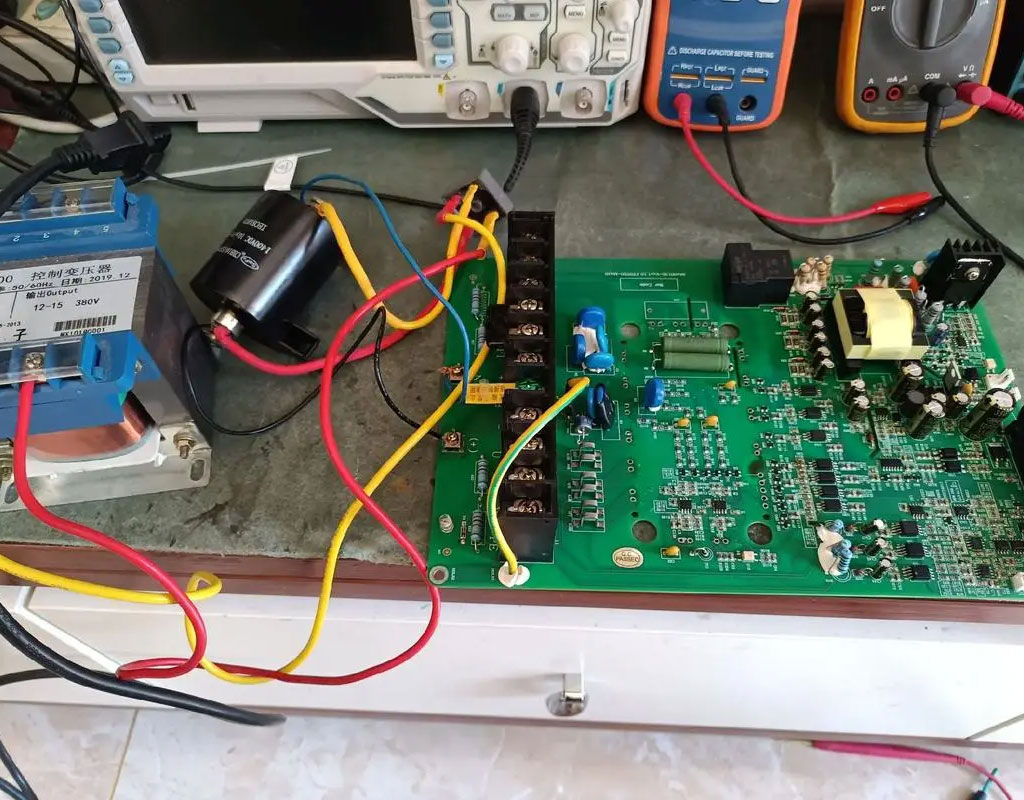

1.4 If everything else is normal after power-on, but there is still no display, the switching power supply may not be working. At this time, you need to unplug the P and N power supplies after power off and check whether the static state of IC3845 is normal (check based on experience). If the static state of IC3845 is normal, the voltage across the 18V/1W voltage regulator diode is about 8V after adding DC voltage to P and N, but the switching power supply does not work. Turn off the power to check whether the rectifier diode on the secondary side of the switching transformer is short-circuited.

1.5 After power-on, the 18V/1W Zener diode has voltage, but there is still no display. You can remove some peripheral wires, including the relay wire plug and the fan wire plug, and check whether the fan or relay is short-circuited.

1.6 After the P and N terminals are powered on, the voltage across the 18V/1W Zener diode is about 8V. Use an oscilloscope to check whether there is a sawtooth wave at the input terminal ④ of IC3845 and whether there is output at the output terminal ⑥.

1.7 Check whether there is a short circuit between the output terminals +5V, ±15V, +24V of the switching power supply and each drive power supply to the ground and between the poles.

2. The keyboard displays normally but cannot be operated

2.1 If the keyboard display is normal, but the function keys cannot be operated, you should check whether the keyboard used matches the main control board (whether it contains IC75179). For machines with internal and external keyboard operations, you should check whether the DIP switch position you set is correct.

2.2 If the display is normal but some buttons cannot be operated, check whether the button micro switch is defective.

3. The potentiometer cannot adjust the speed

3.1 First check whether the control method is correct.

3.2 Check whether the given signal selection and analog input mode parameter settings are valid.

3.3 Check whether the DIP switch settings on the main control board are correct.

3.4 If all of the above are correct, the potentiometer may be defective and the resistance value should be checked to see if it is normal.

4. Overcurrent protection (OC)

4.1 When "FO OC" is displayed on the inverter keyboard and "OC" flashes, you can press the "∧" key to enter the fault query state, and you can find the operating frequency, output current, operating status, etc. at the time of the fault. According to the operating status and output current, you can determine whether the "OC" protection is overload protection or Vce protection (output short circuit, drive circuit failure and interference, etc.).

4.2 If it is determined during the query that the current is too large during acceleration due to heavy load, then adjust the acceleration time and the appropriate V/F characteristic curve appropriately.

4.3 If the inverter jumps to "OC" protection when the motor is not connected and the inverter is running idle, the power should be turned off to check whether the IGBT is damaged, and whether the junction capacitance between the IGBT's freewheeling diode and GE is normal. If normal, the drive circuit needs to be checked: ① Check whether the drive line is plugged in correctly, whether there is offset, and whether it is plugged in vain. ② Check whether the "OC" is caused by poor HALL and line. ③ Check whether the drive circuit amplifier element (such as IC33153, etc.) or the optical coupler is short-circuited. ④ Check whether the drive resistor is open-circuited, short-circuited, or has resistance value changes.

4.4 If “OC” jumps during operation, check whether the motor is blocked (mechanically stuck), causing a sudden change in load current and causing overcurrent.

4.5 If “OC” jumps during deceleration, the deceleration time and deceleration mode need to be adjusted accordingly according to the type and weight of the load.

5. Overload protection (OL)

5.1 When "FO OL" is displayed on the inverter keyboard and "OL" flashes, you can press the "∧" key to enter the fault query state, and you can check the operating frequency, output current, operating status, etc. at the time of the fault. According to the operating status and output current, if the output current is too large, it may be caused by excessive load. At this time, you should adjust the acceleration and deceleration time, V/F curve, torque boost, etc. If it is still overloaded, you should consider reducing the load or replacing the inverter with a larger capacity.

5.2 If the output current is not large when checking the fault, you should check whether the parameters of the electronic thermal overload relay are appropriate.

5.3 Check whether the HALL and wires are defective.

6. Overheat protection (OH)

6.1 Check whether the temperature switch wire is properly plugged in, and use a multimeter to check whether the temperature switch wire is disconnected. If it is disconnected, it can be concluded that the temperature switch wire is broken or the temperature switch is damaged.

6.2 Fan failure causes overheating protection.

6.3 The ambient temperature is too high, the heat dissipation effect is poor, and the internal temperature of the inverter is high, resulting in overheating protection.

6.4 For the inverter with seven-unit IGBT with rectifier bridge, the temperature detection is carried out by using the resistance change of the thermistor inside the IGBT. If the "OH" overheat protection appears, there are the following reasons: ① The comparator is broken and the output is high level. ② The comparison resistance of the comparator changes and the comparison voltage is low. ③ The resistance of the thermistor inside the IGBT is abnormal.

7. Overvoltage protection (OU)

7.1 The inverter has overvoltage protection during deceleration due to large load inertia. At this time, the deceleration time should be extended. If it is still ineffective, a braking unit and a braking resistor can be installed to consume energy.

7.2 Due to the overvoltage protection caused by replacing the power board or main control board, the VpN parameter resistor needs to be adjusted.

7.3 If the input power voltage is much higher than the rated voltage of the inverter, overvoltage may also occur.

8. Undervoltage protection (LU)

8.1 First check whether the input power voltage is normal, whether the wiring is in good condition, and whether there is any phase loss.

8.2 Is the “04” value parameter resistor appropriate?

8.3 Due to the replacement of the power board or the main control board, the undervoltage protection caused by the replacement of the power board or the main control board requires adjustment of the VpN parameter resistor.

8.4 Voltage detection circuit, operational amplifier and other device defects can also cause undervoltage.

9. There is frequency display, but no voltage output

9.1 After the inverter is running, there is a running frequency, but there is no voltage output between U, V, and W. At this time, it is necessary to check whether the carrier frequency parameters are lost.

9.2 If the carrier frequency parameters are normal, you can run the inverter and use an oscilloscope to check whether its drive waveform is normal.

9.3 If the driving waveform is abnormal, you need to check whether the SPWM waveform sent by the main control board CPU is normal. If it is abnormal, the CPU is faulty. If the SPWM waveform of the main control board is normal, you need to cut off the power and replace the 26P cable and try again. If the driving waveform of the driver board is still abnormal, the driving circuit part is faulty and needs to be repaired or replaced.

10. The relay does not close

10.1 First, check whether the input power is abnormal (such as lack of phase).

10.2 Check whether the connection between the power board and the capacitor board is correct and whether there is any looseness.

10.3 Check whether the 26P cable between the main control board and the power board has poor contact or is broken, which causes the REC control signal to be invalid and the relay to fail to energize.

10.4 Damage to components in the relay's energizing circuit may also cause the relay to fail to energize.

10.5 The relay is damaged internally (such as coil breakage, etc.).

Copyright 2025 @ Xiamen Wusu Network Technology Co., Ltd. .All Rights Reserved.Sitemap | Blog | XML | Privacy Policy

Network Supported

Network Supported